Ashwagandha Root Extract vs. Powder: Which Is Better for Supplements and Formulations?

2026-02-02 15:04:54

Executive Summary: Ashwagandha Root Extract vs. Powder for Commercial Applications

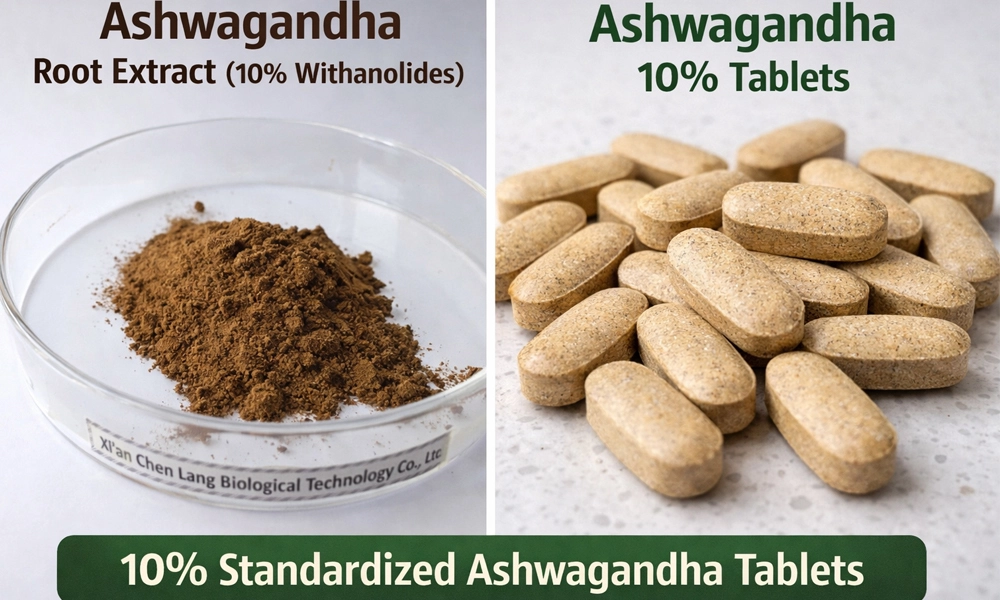

Ashwagandha root extract has become the preferred ingredient form in modern dietary supplements and functional formulations, particularly where consistency, standardization, and scalable production are required. While Ashwagandha root powder remains a traditional option, the practical differences between extract and powder are critical when evaluating raw materials for commercial use.

From an ingredient manufacturing and formulation perspective, Ashwagandha Root Extract offers clear advantages over powder due to its standardized withanolides content, improved solubility behavior, and greater batch-to-batch consistency. Root powder, derived from milled whole roots, naturally exhibits variability in active compound levels, which can complicate dosage accuracy and formulation stability in finished products.

These distinctions are especially relevant for supplement brands, formulators, and OEM/ODM manufacturers operating under strict quality and compliance requirements. As a result, standardized solutions—such as Ashwagandha Root Extract with 10% withanolides—are increasingly selected to support precise formulation control, reliable product performance, and consistent label claims across production batches.

What Is Ashwagandha Root Powder?

Ashwagandha root powder is produced by drying whole Ashwagandha roots and mechanically milling them into a fine powder. As a minimally processed ingredient, it retains the natural composition of the root, including fibers, starches, and minor phytochemicals, alongside withanolides.

From a formulation standpoint, Ashwagandha root powder is a non-standardized material. The withanolides content is determined by the original plant material and can vary significantly between harvests and suppliers. This variability makes it difficult to define precise potency or to rely on consistent active compound levels without extensive incoming material testing.

In finished supplement formulations, root powder also presents practical limitations. Higher inclusion levels are typically required to reach functional withanolides targets, which can affect capsule size, tablet compression, and sensory properties such as taste and mouthfeel. As a result, while Ashwagandha root powder may be suitable for traditional or low-spec applications, it offers limited control in formulations that demand consistency, efficiency, and scalability.

What Is Ashwagandha Root Extract?

Ashwagandha root extract is produced by selectively extracting bioactive compounds from Ashwagandha roots using controlled solvent systems, followed by concentration and drying. Unlike root powder, which reflects the full and variable composition of the raw plant, the extract is designed to concentrate specific functional components—most notably withanolides—into a more consistent and application-ready ingredient.

A defining characteristic of ashwagandha root extract is standardization. By adjusting extraction parameters and validating results through analytical testing, manufacturers can deliver extracts with a defined withanolides content, such as ashwagandha root extract standardized to 10% withanolides. This standardization allows formulators to work with predictable potency, enabling precise dosage calculations and consistent performance across production batches.

From a formulation and supply-chain perspective, ashwagandha root extract functions as an engineered botanical ingredient rather than a raw agricultural material. The reduction of inactive components, combined with improved solubility and handling properties, makes standardized extracts better suited for modern supplement manufacturing, where efficiency, reproducibility, and specification control are essential.

Why Ashwagandha Root Extract Is Often Preferred for Commercial Supplements

In commercial supplement development, ingredient selection is driven by control, predictability, and scalability rather than tradition alone. For this reason, ashwagandha root extract is often favored over root powder in modern formulations, particularly where standardized performance and regulatory readiness are required.

Standardized Withanolides = Predictable Performance

The primary technical advantage of ashwagandha root extract lies in the standardization of withanolides, the key bioactive compounds of Ashwagandha. By delivering a defined withanolides concentration—such as ashwagandha root extract standardized to 10% withanolides—formulators can design products around precise active targets rather than estimated ranges.

This level of standardization supports consistent formulation outcomes, simplifies batch-to-batch quality control, and reduces the need for frequent reformulation. In contrast, non-standardized raw materials require wider safety margins and additional testing to compensate for natural variability, increasing both development time and production risk.

Lower Dose, Better Formulation Flexibility

From a formulation efficiency perspective, ashwagandha root extract allows target withanolides levels to be achieved at significantly lower inclusion rates. This has direct implications for dosage form design, particularly in capsules and tablets, where fill weight and compressibility are critical constraints.

In more complex delivery systems—such as functional powders, beverages, or gummies—lower dosage requirements also help manage taste, mouthfeel, and stability. By minimizing the amount of plant-derived solids introduced into the formulation, standardized extracts provide greater flexibility without compromising specification targets.

Better Fit for Scaling and Global Compliance

As supplement brands scale production and expand into regulated markets, documentation and compliance become as important as formulation performance. Ashwagandha root extract is typically supplied with a complete technical documentation package, including COA, specification sheets, SDS, allergen statements, non-GMO declarations, and traceability information.

These standardized quality documents support internal audits, third-party testing, and regulatory submissions across different regions. For manufacturers and brand owners operating under global compliance frameworks, working with a well-defined ashwagandha root extract specification reduces uncertainty and streamlines supplier qualification processes.

Formulation Considerations by Dosage Form

Capsules & Tablets

For solid dosage forms, performance during encapsulation and tableting is a primary consideration when selecting ashwagandha root extract. Parameters such as flowability, bulk density, compressibility, and excipient compatibility directly influence production stability and finished tablet quality, particularly at higher fill weights.

Based on internal tableting evaluations, ashwagandha root extract standardized to 10% withanolides has been successfully processed into 1000 mg tablets using conventional tableting equipment. During compression, the extract exhibited good compatibility with commonly used excipients, including microcrystalline cellulose, starch-based fillers, and standard flow aids. The blend showed stable flow and compression behavior, with no significant issues related to sticking, capping, or lamination under typical compression forces.

The resulting 1000 mg tablets demonstrated uniform weight, smooth and intact surfaces, and consistent mechanical strength. Material loss during the tableting process was limited, supporting efficient yield and stable production output. From a manufacturing perspective, these characteristics indicate that ashwagandha root extract can be effectively formulated into high-dose tablets while maintaining acceptable appearance and quality standards.

For capsule applications, the standardized nature of ashwagandha root extract allows formulators to achieve defined withanolides targets with lower or more flexible fill weights compared to root powder. This supports cleaner capsule designs and simplifies specification control across production batches.

Functional Beverages & Powders

In liquid and powder-based formulations, ingredient behavior during dispersion is a critical factor. Ashwagandha root extract offers advantages over root powder due to its reduced insoluble matrix and more controlled particle characteristics.

When incorporated into functional powders or beverage premixes, standardized ashwagandha root extract shows improved dispersion performance and lower sedimentation tendency compared to non-extracted root powder. This contributes to more uniform distribution of active compounds and improved stability in reconstituted systems.

From a formulation standpoint, improved dispersion also reduces the need for excessive masking agents or stabilizers, allowing greater flexibility in flavor design and cleaner ingredient declarations.

Gummies and Chewable Formats

For gummies and chewable supplements, formulation constraints differ significantly from traditional solid dosage forms. Flavor impact, thermal stability, and active compound retention are all critical considerations.

The use of ashwagandha root extract enables more precise control over inclusion levels, which helps limit flavor interference and reduces the risk of texture disruption in gel-based systems. Standardized extracts also simplify the calculation of target withanolides content, supporting consistent labeling across production batches.

In addition, the lower inclusion rate associated with ashwagandha root extract helps mitigate active loss during processing steps involving heat or extended mixing, contributing to more reliable finished product specifications.

Quality & Specification Checklist for Ashwagandha Root Extract

For ingredient buyers, formulators, and quality teams, evaluating ashwagandha root extract requires more than a basic specification sheet. Consistent product performance depends on a combination of chemical standardization, physical properties, and supporting documentation. The following checklist outlines the key parameters that should be reviewed when sourcing standardized Ashwagandha extracts for commercial applications.

Withanolides Content and Analytical Method

The defining quality parameter of ashwagandha root extract is its withanolides content. Buyers should confirm not only the declared percentage—such as ashwagandha root extract standardized to 10% withanolides—but also the analytical method used to determine this value.

♦Verification by HPLC or UPLC is recommended

♦Clear identification of reference standards and test conditions

♦Defined specification range rather than a single-point value

♦Consistent analytical methodology is essential to ensure comparability between batches and suppliers.

Extraction System and Standardization Approach

Understanding how the extract is produced provides insight into its functional behavior and reproducibility.

♦Type of extraction system used (e.g., aqueous, hydroalcoholic)

♦Whether the extract is naturally concentrated or standardized by blending

♦Presence and disclosure of carriers or excipients, if applicable

Transparent disclosure supports better formulation predictability and regulatory review.

Physical and Functional Specifications

In addition to chemical composition, the physical characteristics of ashwagandha root extract directly affect handling and formulation performance.

Key parameters to review include:

♦Moisture content

♦Particle size distribution

♦Bulk and tapped density

♦Flowability and dispersion behavior

♦Color, odor, and visual uniformity

These attributes influence blending efficiency, compression behavior, and overall process stability.

Contaminant and Safety Controls

As a botanical ingredient, ashwagandha root extract must meet applicable safety and compliance standards.

Recommended testing parameters include:

♦Microbiological limits

♦Heavy metals

♦Pesticide residues

♦Residual solvents (where applicable)

Compliance with regional regulatory expectations should be supported by current test reports.

Technical Documentation and Traceability

Reliable suppliers of ashwagandha root extract should provide a complete documentation package to support quality assurance and audits.

Essential documents typically include:

♦Certificate of Analysis (COA)

♦Detailed specification sheet

♦Safety Data Sheet (SDS)

♦Allergen and non-GMO statements

♦Batch identification and traceability information

Comprehensive documentation reduces qualification time and supports long-term supply continuity.

Specification Stability and Supply Consistency

Beyond individual test results, buyers should assess a supplier’s ability to maintain consistent specifications over time.

Indicators of supply reliability include:

♦Demonstrated batch-to-batch consistency

♦Defined quality control procedures

♦Capability to support standardized grades, such as 10% withanolides, on a continuous basis

This level of consistency is particularly important for brands and manufacturers operating at scale.

How to Choose the Right Ashwagandha Root Extract Specification

Selecting the appropriate ashwagandha extract withanolides specification is a technical decision that should be aligned with formulation goals, dosage form, and target market requirements. Rather than focusing solely on raw material price, formulators and buyers benefit from evaluating extract specifications based on performance, efficiency, and long-term consistency.

Common Withanolides Options and Their Practical Applications

Commercially available ashwagandha root extract products are typically differentiated by their standardized withanolides content, most commonly at 2.5%, 5%, or 10%. Each specification serves different formulation needs.

•2.5% withanolides

This specification is often used in traditional-style supplements or multi-herbal formulations where Ashwagandha is one of several active ingredients. Higher inclusion levels are generally required, which may limit its suitability for compact dosage forms or high-dose tablets.

•5% withanolides

A mid-range option that balances potency and flexibility, commonly applied in general wellness supplements. While more efficient than lower-grade extracts, formulators may still need to account for dosage constraints in tablets, capsules, or gummies.

•10% withanolides

Ashwagandha root extract standardized to 10% withanolides is frequently selected for modern supplement formulations that require precise dosing, strong specification control, and efficient use of space within the dosage form. The higher active concentration allows formulators to achieve target withanolides levels at lower inclusion rates, improving formulation flexibility and process efficiency.

From a cost perspective, evaluation should be based on cost-in-use rather than unit price alone. Higher-potency extracts often reduce total material usage, simplify formulation design, and improve production yield, offsetting differences in raw material cost.

Frequently Asked Questions About Ashwagandha Root Extract and Powder

Is ashwagandha extract stronger than powder?

From a formulation perspective, ashwagandha root extract is considered more potent than root powder because it delivers a concentrated and standardized level of withanolides. Root powder reflects the natural composition of the plant and typically contains lower and variable active compound levels. As a result, extracts allow formulators to achieve target withanolides content at lower inclusion rates and with greater consistency.

What withanolides percentage is best for supplements?

The optimal withanolides percentage depends on the dosage form, target serving size, and formulation constraints. Lower concentrations may be suitable for traditional or multi-herbal products, while higher concentrations support efficient formulation and precise dosing. In many modern supplement applications, ashwagandha root extract standardized to 10% withanolides provides a practical balance between potency, flexibility, and process efficiency.

Can I use ashwagandha root powder in tablets or gummies?

Ashwagandha root powder can be used in tablets or gummies, but higher inclusion levels are usually required to reach functional withanolides targets. This can affect tablet size, texture, taste, and processing efficiency. For dosage forms with limited space or strict sensory requirements, ashwagandha root extract is often easier to formulate and control.

How do I verify withanolides content and authenticity?

Verification of withanolides content should be based on validated analytical methods such as HPLC or UPLC, using clearly defined reference standards. Buyers should review the testing methodology listed on the COA and confirm consistency across multiple batches. Reliable suppliers are able to provide transparent analytical data rather than single-point values without context.

What documents should an ashwagandha extract supplier provide?

A qualified ashwagandha root extract supplier should provide a complete technical documentation package. This typically includes a Certificate of Analysis (COA), specification sheet, Safety Data Sheet (SDS), allergen and non-GMO statements, and batch traceability information. These documents support quality assurance, regulatory review, and long-term supply stability.

Conclusion

When comparing ashwagandha root extract vs. powder form, the differences are most evident in formulation control, consistency, and suitability for commercial-scale production. Ashwagandha root powder remains an option for traditional or low-spec applications, but its natural variability and higher usage levels limit its practicality in modern supplement manufacturing.

In contrast, ashwagandha root extract is engineered for performance-driven formulations. Through controlled extraction and standardization, it delivers defined withanolides content, improved processing behavior, and reliable batch-to-batch consistency. These characteristics make standardized extracts—particularly ashwagandha root extract with 10% withanolides—well suited for supplements and functional products that require precise dosing, scalable production, and consistent label claims.

As a manufacturer and supplier of botanical extracts, CHEN LANG BIO TECH produces standardized ashwagandha extract withanolides with a focus on specification control, formulation compatibility, and supply reliability. Our extracts are developed to meet the technical and quality requirements of supplement brands, formulators, and OEM/ODM partners worldwide.

For detailed specifications, COA, samples, or technical support related to ashwagandha root extract (10% withanolides), please contact CHEN LANG BIO TECH send to email: admin@chenlangbio.com to connect with our technical and sales team.

Send Inquiry

Related Industry Knowledge

- Hydroxypinacolone Retinoate vs Retinol: Key Differences Formulators Should Know

- Unlocking Radiance: The Science Behind 3-O Ethyl Ascorbic Acid

- Vitamin E Powder for Functional Foods—Why?

- How Does High-Purity Silymarin in Milk Thistle Extract Support Liver Health?

- Why Durian Fruit Powder is Trending

- Does Bakuchiol Clog Pores

- Fisetin Powder Antioxidant Activity and Health Supplement

- Chrysin Benefits

- What does Garlic Extract Powder Allicin Do to Bacteria

- How Does Kava Kavalactone Powder Affect the Brain