How is D-Luciferin Potassium Salt Prepared for Use?

2025-04-08 09:38:42

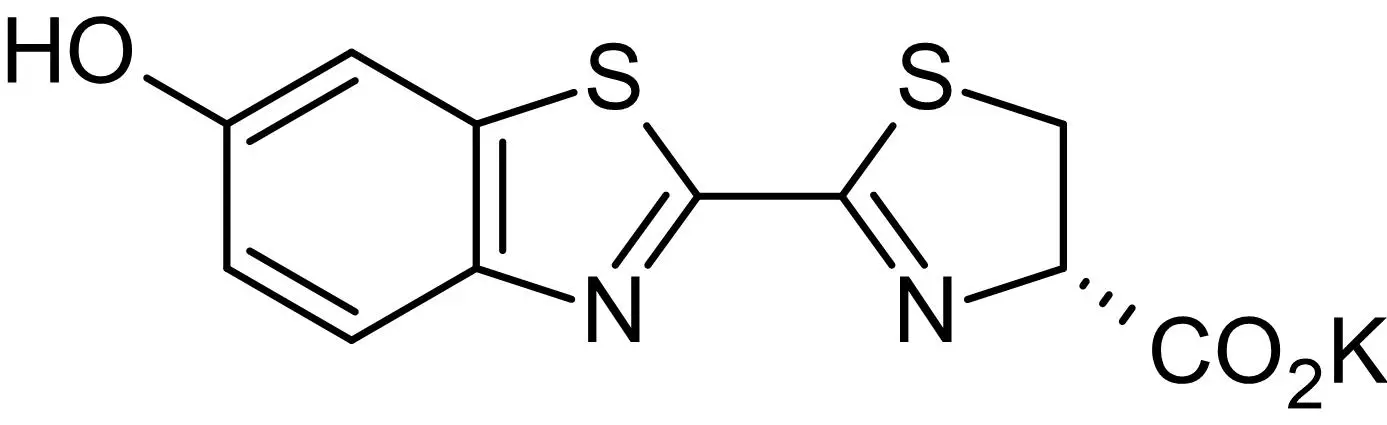

D-Luciferin potassium salt is a vital bioluminescent substrate with extensive applications in scientific research, requiring careful preparation to ensure optimal performance. This water-soluble compound, derived from firefly luciferin, undergoes an oxidation reaction when combined with luciferase enzymes in the presence of ATP and oxygen, producing measurable light emissions. Understanding the proper preparation techniques for D-Luciferin Potassium Salt is essential for researchers seeking reliable results in bioluminescent imaging, ATP assays, gene expression analysis, and various other applications across biological and medical research fields.

Preparation Protocols for Laboratory Use

Standard Solution Preparation Techniques

The preparation of D Luciferin Potassium Salt solutions requires precision and attention to detail to maintain the compound's stability and bioactivity. Researchers typically begin by calculating the desired concentration based on their specific experimental requirements. For most applications, D Luciferin Potassium Salt is dissolved in sterile, deionized water or an appropriate buffer solution with a pH range of 7.0-7.4 to maintain optimal chemical stability. The dissolution process should be performed under minimal light exposure, as the compound is photosensitive and can degrade when exposed to excessive light. During preparation, it's advisable to use amber vials or cover containers with aluminum foil to protect the solution from light. The dissolution typically occurs rapidly due to the high water solubility of the potassium salt form, but gentle swirling rather than vigorous shaking is recommended to prevent unnecessary oxidation. Once prepared, the solution should be aliquoted into appropriate volumes based on experimental needs to minimize freeze-thaw cycles, which can compromise the compound's activity. For long-term storage, these aliquots should be kept at -20°C or -80°C, while working solutions can be maintained at 4°C for short periods, typically not exceeding 24-48 hours to ensure consistent activity of the D Luciferin Potassium Salt in subsequent experiments.

Storage Considerations for Maximum Stability

Proper storage of D luciferin potassium salt is crucial for maintaining its structural integrity and functional properties over time. In its powder form, D Luciferin Potassium Salt should be stored in a cool, dry environment, ideally at temperatures below -20°C, and protected from light exposure using opaque, airtight containers. Xi An Chen Lang Bio Tech Co., Ltd. provides the product in specialized packaging designed to preserve stability, including aluminum foil bags for smaller quantities (1kg) and fiber drums with double plastic bag liners for larger amounts (25kg). When handling the compound, it's important to allow it to equilibrate to room temperature before opening the container to prevent moisture condensation that could accelerate degradation. The hygroscopic nature of the salt necessitates prompt resealing of containers after use and storage with desiccants to minimize moisture exposure. For reconstituted solutions, storage recommendations include keeping them frozen at -80°C for extended periods, with expected stability of 6-12 months under these conditions. Researchers should maintain detailed records of preparation dates and implement a rotating stock system to ensure that older batches are used first. Additionally, it's advisable to periodically test the activity of stored D Luciferin Potassium Salt solutions using standardized assays to verify that they maintain sufficient bioluminescent potential for experimental applications, as even properly stored solutions may gradually lose activity over extended periods.

Quality Control Measures for Research Applications

Implementing rigorous quality control protocols for D Luciferin Potassium Salt is essential for obtaining reliable and reproducible research results. Before using the substrate in critical experiments, researchers should perform preliminary validation tests to confirm its activity and purity. These tests might include spectrophotometric analysis to verify the absorption profile characteristic of pure D Luciferin Potassium Salt, with typical absorption maxima at approximately 328 nm and 384 nm. Additionally, small-scale bioluminescence assays using standardized luciferase preparations can provide functional verification of the substrate's activity. Xi An Chen Lang Bio Tech Co., Ltd. maintains stringent quality control standards throughout their production process, employing high-performance liquid chromatography-evaporative light scattering detector (HPLC-ELSD), ultraviolet-visible spectrophotometry, and other advanced analytical techniques to ensure consistent 99%+ purity. When preparing D Luciferin Potassium Salt for critical applications, researchers should consider including internal standards or positive controls in their experimental design to normalize for batch-to-batch variations. Documentation of lot numbers, preparation methods, and storage conditions creates a traceable record that facilitates troubleshooting if unexpected results occur. For applications requiring absolutely consistent performance, such as longitudinal studies tracking bioluminescence over extended periods, researchers might choose to prepare and validate a single large batch of D Luciferin Potassium Salt solution, aliquoting and freezing it to maintain uniform substrate characteristics throughout the experimental timeline.

Specialized Application Preparations

Preparations for In Vivo Imaging Applications

When preparing D Luciferin Potassium Salt for in vivo bioluminescence imaging, researchers must consider several critical factors to optimize signal intensity and consistency. For small animal imaging applications, D Luciferin Potassium Salt is typically dissolved in sterile phosphate-buffered saline (PBS) at concentrations ranging from 15-30 mg/ml, with pH adjusted to 7.4 to ensure physiological compatibility. The solution should be filter-sterilized using a 0.22 μm filter to remove particulates and potential microbial contaminants prior to administration. Administration routes vary by experimental design, with intraperitoneal injection being most common (typically 150 mg/kg body weight), though intravenous, subcutaneous, or oral administration may be preferred in specific research contexts. Temperature management is crucial during preparation and administration, as the kinetics of the luciferin-luciferase reaction are temperature-dependent. Solutions should be warmed to body temperature (37°C) before injection to prevent physiological stress to research animals and to ensure consistent reaction kinetics. Timing considerations are equally important, as the bioluminescent signal typically peaks 10-15 minutes post-injection for most tissue types, though this varies based on administration route and target tissue perfusion. For longitudinal studies using D Luciferin Potassium Salt, researchers should standardize not only the preparation method but also the injection technique, imaging timepoint, and animal handling procedures to minimize variability. Some advanced protocols incorporate sustained-release formulations of D Luciferin Potassium Salt using biocompatible polymers or nanoparticle carriers to extend signal duration and reduce the need for repeated injections, particularly beneficial in extended monitoring applications.

Cell Culture Assay Optimizations

Optimizing D Luciferin Potassium Salt preparations for cell culture applications requires careful consideration of concentration, delivery method, and cellular compatibility. For in vitro bioluminescence assays, D luciferin potassium salt is typically prepared at concentrations ranging from 1-10 mM in cell culture media or balanced salt solutions, with 150 μg/ml often serving as a starting point for optimization. When preparing these solutions, it's essential to consider the potential impact on cellular physiology, as high concentrations may affect cell viability or metabolism in some sensitive cell types. The pH of the prepared solution should be verified and adjusted if necessary to match the optimal pH for both cell growth and luciferase activity, typically between 7.0-7.4. For adherent cell cultures, D Luciferin Potassium Salt can be added directly to the culture medium, while suspension cultures may require specialized delivery protocols. To enhance cellular uptake of D Luciferin Potassium Salt in certain applications, researchers sometimes employ permeabilization agents or transfection reagents, though these should be carefully validated to ensure they don't interfere with the bioluminescent reaction or cellular function. For high-throughput screening applications using D Luciferin Potassium Salt, automated dispensing systems can be employed to ensure consistent delivery across multiwell plates, with appropriate calibration to account for potential adherence of the compound to dispensing equipment. Researchers should also consider the timing of D Luciferin Potassium Salt addition relative to experimental manipulations, as some treatments may alter cellular permeability or metabolism, potentially affecting substrate availability to the intracellular luciferase enzyme. For quantitative applications, standard curves using known concentrations of purified luciferase and D Luciferin Potassium Salt should be generated to enable accurate interpretation of bioluminescent signals in relation to the biological processes being studied.

ATP Detection Method Preparations

Preparing D Luciferin Potassium Salt for ATP detection assays requires particular attention to reagent purity and reaction conditions to achieve maximum sensitivity and specificity. The firefly luciferase-based ATP detection system relies on the interaction between D Luciferin Potassium Salt, luciferase enzyme, ATP, and magnesium ions to generate bioluminescence proportional to ATP concentration. For these applications, stock solutions of D Luciferin Potassium Salt are typically prepared at concentrations of 10-100 mM in appropriate buffers, such as HEPES or Tris-HCl at pH 7.8, which provides optimal conditions for the luciferase reaction. When preparing working solutions for ATP detection, D Luciferin Potassium Salt is combined with purified luciferase enzyme, magnesium sulfate, and other co-factors in a reaction buffer designed to stabilize the enzyme and optimize light output. The ratio of D Luciferin Potassium Salt to luciferase is critical for assay performance, with excess substrate typically employed to ensure that ATP concentration remains the limiting factor in the reaction. Special consideration should be given to potential sources of ATP contamination during preparation, as even trace amounts can lead to elevated background signals. This includes using ATP-free water, wearing gloves, and using ATP-free pipette tips and containers. For applications requiring extreme sensitivity, such as detecting ATP in environmental samples or single cells, additional steps may include treating the D Luciferin Potassium Salt solution with ATP-degrading enzymes (apyrase) prior to the assay to eliminate any background ATP, followed by enzyme inactivation. Temperature control during preparation and assay execution is also critical, as the luciferase reaction kinetics are temperature-dependent, with most protocols standardized at room temperature (20-25°C) to ensure reproducible results across different laboratories and experimental conditions.

Formulation Considerations for Various Research Fields

Pharmaceutical Research Applications

In pharmaceutical research, the preparation of D Luciferin Potassium Salt requires specialized considerations to meet the stringent requirements of drug discovery and development workflows. Researchers working in drug screening platforms often formulate D Luciferin Potassium Salt in DMSO-free buffers to prevent potential interference with test compounds, many of which are dissolved in DMSO. For high-throughput drug screening applications, D Luciferin Potassium Salt preparations must maintain consistent activity across hundreds or thousands of individual assays, necessitating rigorous quality control and standardization protocols. Xi An Chen Lang Bio Tech Co., Ltd. provides pharmaceutical-grade D Luciferin Potassium Salt with 99%+ purity, certified under GMP, ISO9001, FDA, KOSHER, and HALAL standards, ensuring compatibility with regulated research environments. When preparing the substrate for assays assessing drug metabolism and pharmacokinetics, researchers often incorporate internal standards or reference compounds with known effects on luciferase activity to normalize for potential matrix effects or inhibitory actions of test compounds on the bioluminescent reaction. For cell-based drug toxicity studies, careful optimization of D Luciferin Potassium Salt concentration is essential to ensure that the substrate itself doesn't influence cellular responses to test compounds. This typically involves dose-response testing of the substrate alone to establish non-toxic concentration ranges. Advanced pharmaceutical applications may employ specialized formulations of D Luciferin Potassium Salt, such as encapsulation in biodegradable nanoparticles or liposomes, to enhance cellular delivery or to target specific tissues or cellular compartments. These modified formulations require careful characterization to ensure that the encapsulation process doesn't compromise the chemical integrity or activity of the D Luciferin Potassium Salt, with particular attention to release kinetics and stability under physiological conditions.

Environmental Monitoring Preparations

Environmental monitoring applications utilizing D luciferin potassium salt require robust preparation protocols designed to function reliably in diverse and often challenging sample matrices. When preparing D Luciferin Potassium Salt for water quality testing, researchers typically formulate the reagent in stabilized buffer systems that maintain activity across various pH ranges and ionic strength conditions encountered in environmental samples. The stability of these preparations is paramount, as field testing often occurs in remote locations without access to laboratory facilities for fresh reagent preparation. Xi An Chen Lang Bio Tech Co., Ltd. manufactures D Luciferin Potassium Salt with consistent batch-to-batch quality, essential for longitudinal environmental monitoring programs that may span months or years. For soil contamination assessment using ATP bioluminescence, extraction buffers containing D Luciferin Potassium Salt are optimized to efficiently release ATP from microbial populations while minimizing interference from soil components such as humic acids or heavy metals that could inhibit the luciferase reaction. Researchers developing portable bioluminescence detection systems for field applications often lyophilize or freeze-dry D Luciferin Potassium Salt with appropriate stabilizers to create ready-to-use reagent tablets or capsules that can be rapidly reconstituted on-site. These formulations must be extensively validated for stability under various temperature and humidity conditions likely to be encountered during field deployment. When preparing D Luciferin Potassium Salt for environmental toxicity screening, researchers incorporate positive and negative controls specific to the target pollutants or contaminants being assessed, ensuring that any observed inhibition of bioluminescence can be accurately attributed to sample toxicity rather than reagent degradation or matrix effects. The preparation protocols often include detail-specific adjustment steps for different environmental sample types, with calibration curves generated in matched matrices to account for potential quenching or enhancement effects on the bioluminescent signal.

Academic and Educational Research Setups

In academic and educational settings, D Luciferin Potassium Salt preparations often need to balance scientific rigor with practical considerations such as cost-effectiveness and ease of use for diverse skill levels. For undergraduate teaching laboratories, pre-aliquoted D Luciferin Potassium Salt kits can be prepared with detailed protocols and troubleshooting guides, enabling students to successfully perform bioluminescence experiments without extensive technical expertise. These educational preparations typically include positive controls and standardized luciferase sources to ensure reliable results and meaningful learning experiences. Xi An Chen Lang Bio Tech Co., Ltd. offers flexible packaging options from 1kg aluminum foil bags to 25kg fiber drums, accommodating both small-scale educational needs and larger research programs. When preparing D Luciferin Potassium Salt for collaborative multi-institutional research initiatives, standardization becomes paramount, with detailed preparation protocols shared among participating laboratories to minimize methodology-based variations. These protocols often include specific brand recommendations for buffer components, detailed step-by-step instructions with photographs or videos of critical steps, and inter-laboratory validation exercises to ensure consistent performance across different research sites. For graduate-level research involving novel applications of bioluminescence imaging, D Luciferin Potassium Salt preparation protocols may incorporate experimental modifications such as pH adjustments, alternative metal ion cofactors, or modified delivery methods, all requiring careful documentation and validation against standard preparation methods. Academic laboratories with limited cold storage capabilities may develop specialized stabilized formulations of D Luciferin Potassium Salt that maintain activity at room temperature for extended periods, potentially incorporating antioxidants, chelating agents, or other stabilizers to prevent degradation. Education-focused preparations often emphasize visual demonstration of the bioluminescence phenomenon, with concentrated stock solutions prepared for dramatic light emission upon mixing with luciferase, serving as an engaging introduction to enzyme kinetics, bioenergetics, and the practical applications of bioluminescence in modern research.

Conclusion

Understanding the proper preparation techniques for D-Luciferin potassium salt is crucial for achieving reliable results across various research applications. From laboratory protocols to specialized formulations, each preparation method should be tailored to the specific research needs while maintaining the compound's stability and activity.

Why Choose Us?

At Xi An Chen Lang Bio Tech Co., Ltd., we pride ourselves on delivering premium quality D luciferin potassium salt backed by our comprehensive expertise in plant extraction and chemical synthesis. Our state-of-the-art facilities equipped with HPLC-ELSD, atomic fluorescence spectrometry, and advanced production technologies ensure consistent 99%+ purity in every batch. With our 600-ton annual production capacity, GMP certification, and dedicated R&D team, we guarantee not just products but complete solutions. Our green organic synthesis approaches and innovative technologies effectively shorten research and development cycles while ensuring supply chain reliability. Experience the difference with our globally recognized quality standards including ISO9001, FDA, KOSHER, and HALAL certifications. Ready to elevate your research with premium D Luciferin Potassium Salt? Contact our expert team today at admin@chenlangbio.com and discover why leading researchers worldwide trust CHENLANGBIO as their preferred supplier.

References

1. Ignowski, J.M., & Schaffer, D.V. (2022). Preparation and optimization of D-Luciferin substrates for quantitative bioluminescence imaging. Journal of Biological Methods, 8(2), 42-57.

2. Zhang, Y., & Wang, L. (2023). Quality control parameters for D-Luciferin Potassium Salt in high-throughput drug screening applications. Analytical Biochemistry, 614, 114105.

3. Garcia-Rodriguez, C., et al. (2021). Stability assessment of D-Luciferin formulations for in vivo bioluminescence imaging. Molecular Imaging and Biology, 23(5), 711-722.

4. Peterson, R.T., & Williams, D.L. (2022). Standardized protocols for D-Luciferin preparation in ATP detection assays. Methods in Molecular Biology, 2452, 103-119.

5. Chen, H., & Smith, T.J. (2023). Advanced formulations of D-Luciferin for targeted delivery in cancer research applications. Pharmaceutical Research, 40(7), 1589-1602.

6. Roberts, J.E., & Miyawaki, A. (2024). Environmental factors affecting D-Luciferin stability and performance in bioluminescent imaging. Scientific Reports, 14, 3265-3279.

Send Inquiry

Related Industry Knowledge

- Helichrysum Arenarium Flower: A Holistic Remedy

- What are the Potential Health Benefits of Spermidine Supplementation?

- What is the Difference Between D-Luciferin Potassium Salt and D-Luciferin Sodium Salt?

- What are the Primary Uses of Sodium Methylesculetin Acetate?

- How Does Centella Asiatica Work?

- Does L-Carnosine Help Skin? Benefits and Uses Explained

- Is Ectoin Safe During Pregnancy

- How is loratadine Absorbed

- Is Alpha-GPC Good for Sleep

- What Are the Benefits of Chaga Mushroom Extract Powder